Fallshaw

Celebrating over 100 years of Australian manufacturing

Celebrating over 100 years: 1920 to 2025

Spanning three generations of family, Fallshaw is an Australian manufacturing business who have proudly been designing and manufacturing high-quality wheels and castors in Australia for over 100 years.

Our Mission

We can help our customers to improve safety, productivity and profit in any process that involves pushing, pulling or lifting. We work with:

-

Healthcare, commercial and industrial original equipment manufacturers (OEMs) to offer components or complementary products, that either reduce the lowest total cost of ownership, or provide enhanced product features to increase the saleability or value of their OEM equipment.

Healthcare facilities to improve outcomes in their push-pull processes and patient safety.

Industrial end users to improve their move-safe processes.

Our Service

Our sales representatives work hard to tailor solutions to suit individual customer’s needs.

We are committed to:

Offering a friendly and effective approach to rapid response, convenience and reliability in a manner customised to suit our customer’s needs.

Helping our customers to improve safety, productivity and profit in any process that involves pushing, pulling or lifting.

Our Promise

We comply to rigorous quality-specifications and deliver high-quality innovative products which are designed to perform every time. Quality basics of Fallshaw Core castors:

A 3-year warranty on castors.

Corrosion resistance 3 times the Australian standard.

Attention to detail and quality materials:

Stainless steel brake springs (not heat-treated mild steel that can embrittle).

Steel that is pickled and oiled (not black steel with associated streaky-plating).

Coined ball tracks to prevent brinelling (stops sloppy castors as ball tracks wear-down).

Head race rivets in high-quality steel that won’t elongate or snap under impact.

UV stabilizers in plastic parts so colours stay true and parts don’t become brittle.

Our Values

At our core:

We believe in Australian manufacturing and value its importance.

We strive to produce high quality products, and think anew about material selection and the best manufacturing technology.

We strive to be innovative.

We value the ability to transform and adapt to the changing climate.

We value intelligently simple and smart approaches to designing for both form and function.

We value customer relations.

Solutions to safely push, pull and lift

Product design

An intelligently simple, smart approach to designing for both form and function. Our innovative mobility products are deceptively simple and elegant. The interface is intuitive and easy to use.

We design for form and function with contemporary styling and without unnecessary components or material.

Our products are not constrained by traditional approaches. We enjoy doing things differently we think anew about material selection and manufacturing technology and we radically reinterpret mobility product design. Our greatest compliment is when our customers forget about our mobility products. What do we mean by that?

Castor design

Castors need to be a considered part of the overall design

-

Furniture castors should be a considered part of furniture design, with colour, finish and style seamlessly blending to the point that the castors are just a part of the whole, rather than an afterthought.

-

Castors used on trolleys should steer true with minimal push effort, great ride comfort and brakes that work effectively every time—when castors are designed well people are not conscious of how a trolley moves—it just happens.

-

Serious working castors should have long product life with minimal and easy preventative maintenance—castors should not cause interruptions to equipment use due to high wear rates or breakdowns—they should soldier on unnoticed.

Materials handling equipment

Intelligently designed for simplicity

-

Materials handling equipment should have control panels so intuitive that you don’t need to read the instruction manual or require more than five minutes of training (the hierarchy of information and graphic design should enhance quick understanding of key information).

-

Be safe to use (designed to be fail-safe and ‘idiot proof’ with reliable attention to detail in the use of back off bars, emergency stops, safety cages, multiple load trigger devices and other features designed to ensure the equipment cannot harm users or bystanders).

-

Have refined design (no sharp edges, resolved panelling, attractive control panels, water resistance).

Have thoughtful ergonomics in terms of handle heights, small foot prints, load distribution, pivot points and general sizing.

Our history

Over 100 years of Australian manufacturing

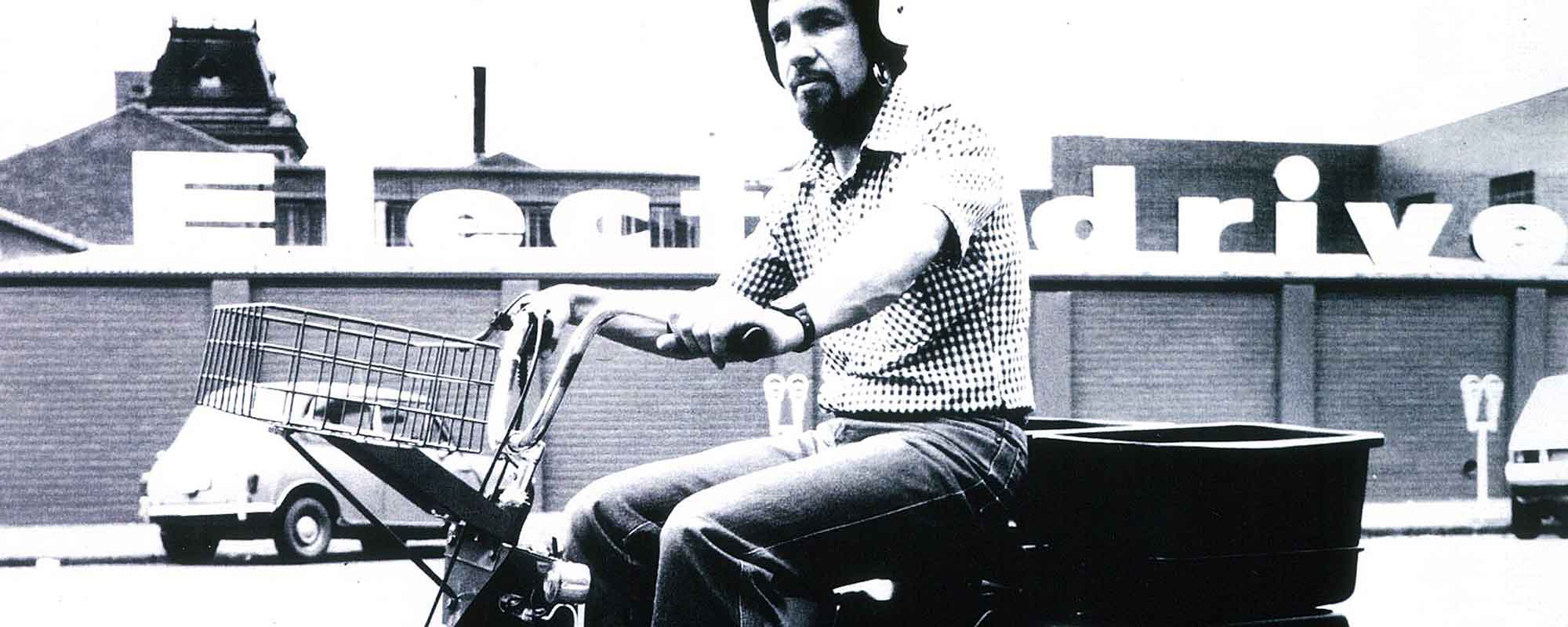

Fallshaw and Electrodrive both have engineering roots and proud histories in designing and manufacturing products to world-class standards in Australia. With core capabilities in competitive manufacturing, our mobility products have a robust quality.

The Fallshaw history timeline

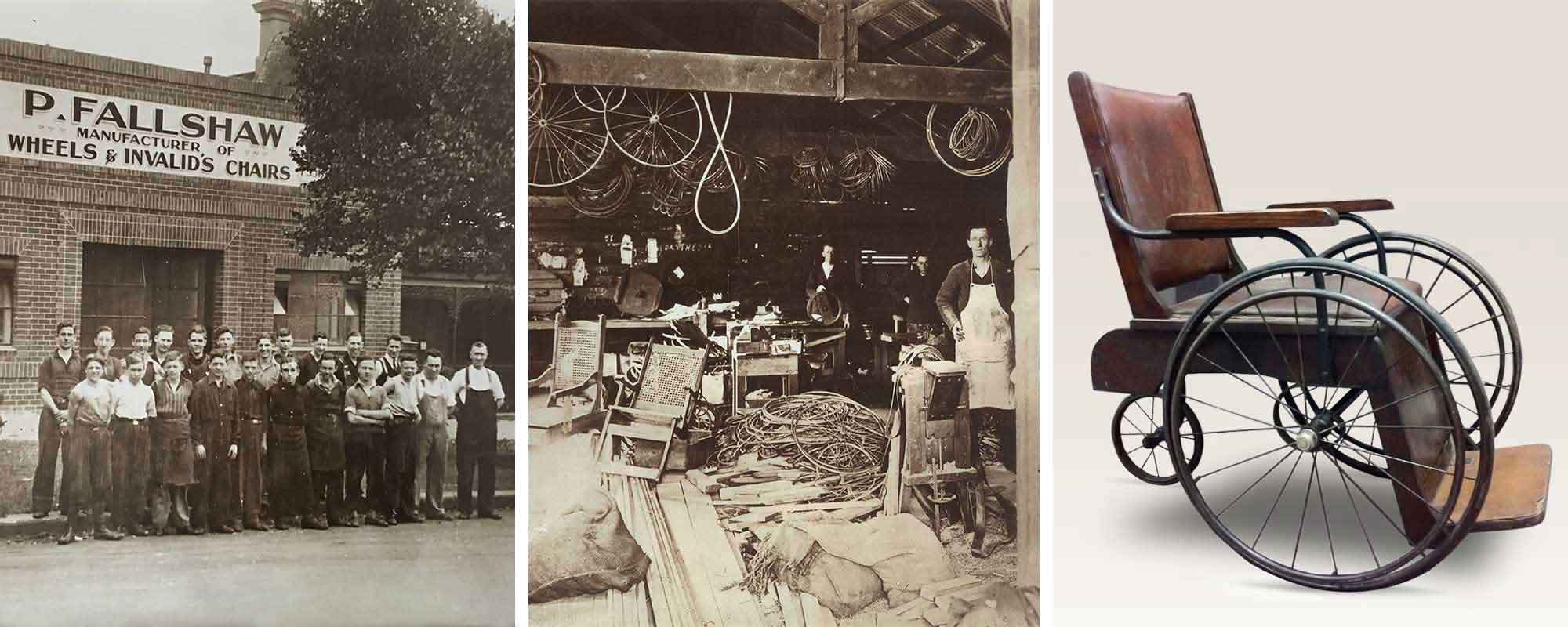

1920

The company was founded by Percy Fallshaw who started making wheelchairs in 1920. The workshop was based in North Melbourne and had between 20 to 30 employees.

Wooden chairs, couches and carriages were made for patients, as well as performing repairs, alterations, custom designs and fitting pneumatic tyres to chairs.

1960s

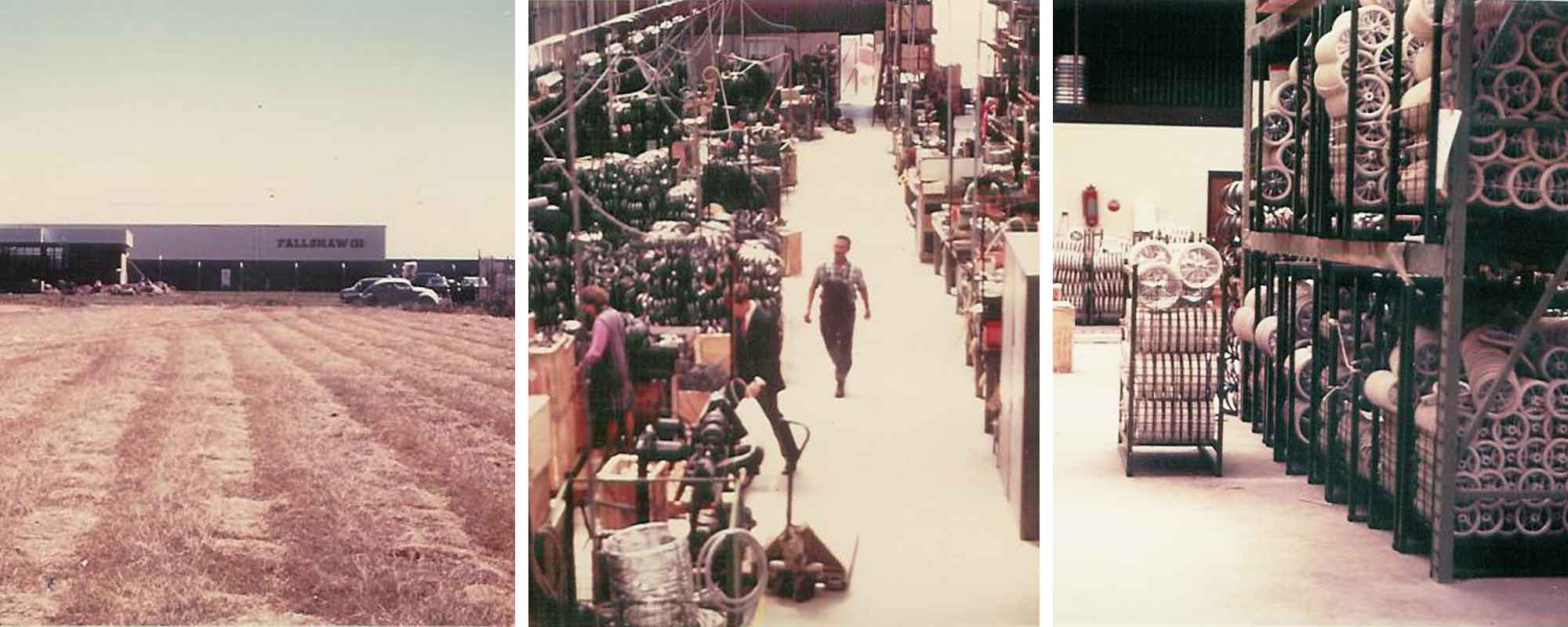

During the 1960s, the company was managed by Percy’s son, Robert Fallshaw. Rob lead Fallshaw for the next 45 years, under whose leadership the company expanded into making castors and developing manufacturing expertise.

Building an enviable sales network, Fallshaw become one of the world’s leading castor companies. Regrettably Robert passed away in 2005.

1972

Eight acres of land was purchased in Sunshine North, Victoria, where the Fallshaw factory was then established.

Wheels and castors were manufactured from this premises, and continues today.

2007

Robert’s daughter, Jo Fallshaw, became the Managing Director and owner, continuing the tradition of developing innovative products, and manufacturing well-designed, cost-effective, quality castors, delivered in-full and on-time with great service and technical support.

2012

Jo Fallshaw acquired Electrodrive, with its own proud history in design, manufacture and servicing of powered materials handling products.

This has enabled Fallshaw and Electrodrive to combine product portfolios and expertise to expand into the broader portfolio of mobility solutions and products.

2016

Fallshaw Group was establised with the following brands: Fallshaw, Electrodrive, Liftmaster, Castors and Industrial, Scissor Lifts Australia, Serviced Equipment, Custom Engineered Solutions.

Today the Fallshaw Group is a single-source solutions provider in materials handling. As experts in mindful moving, our aim is to improve our customer’s safety, productivity and profit in any work process involving pushing, pulling or lifting.